Waste salt drying industry

CONTACT US

If you need, please contact us in time!

Contacts:Ms Annie Shi

Telephone:+86-519-88908088

Mobile:+86-15861862227

Address:No.68 Shunhe Road, Jiaoxi Zhenglu Town, Changzhou City 213116, Jiangsu,China

Waste salt drying industry

Sucralose dedicated bubbling fluidized bed drying production line

sucralose (TGS), by the British Tate & Lyle (Tate & Lyie) jointly developed with the University of London and patented a new type of sweetener in 1976.

Detailed description

Sucralose dedicated bubbling fluidized bed drying production line

project description:

Sucralose (TGS), by the British Tate & Lyle (Tate & Lyie) jointly developed with the University of London and patented a new type of sweetener in 1976. It is the only sugar as raw material, functional sweetener, the original trade name Splenda, sugar sweetness up to 600 times. This sweetener has no energy, sweet and juicy, sweet and pure, high security and so on. It is one of the most outstanding features of the sweetener.

Material Overview:

Sucralose (TGS), by the British Tate & Lyle (Tate & Lyie) jointly developed with the University of London and patented a new type of sweetener in 1976. It is the only sugar as raw material, functional sweetener, the original trade name Splenda, sugar sweetness up to 600 times. This sweetener has no energy, sweet and juicy, sweet and pure, high security and so on. It is one of the most outstanding features of the sweetener.

Sucralose sweetener is approved for use in our country. Its sweetness is about 600 times that of sucrose, pure sweetness, sweetness and quality of sweetness characteristics very similar to sucrose. In general food processing and storage are very stable, water-soluble good, suitable for all kinds of food processing. China provides for beverages, pickles, seasonings, preparation of wine, ice cream, cakes, biscuits, bread and many other fields.

working principle:

After the air is purified and heated, introduced from the bottom induced draft fan through the hole hopper screen. In the studio, by mixing and fluidization negative pressure is formed, after the water is evaporated and removed rapidly, fast drying material.

Features:

◎ fluidized bed is round structure to avoid dead ends.

◎ the hopper stirring to avoid agglomeration of raw material and forming canal of flow when dry.

◎ The turn dump Reap prompt and thorough, can also be designed as request access to material systems.

◎ Seal negative pressure operation, airflow through the filter. Easy to operate, easy to clean.

◎ drying speed, temperature symmetry, each batch of drying time is generally 20-30 minutes, depending on the material may be.

Adaptation Material:

◎ Mechanism screw extrusion particles, rock particles, high speed mixing wet granules.

◎ medicine, food, feed, chemical and other fields wet granules dried and powdered materials.

◎ large particles, small block, sticky block granular materials.

◎ dry volume change material konjac.

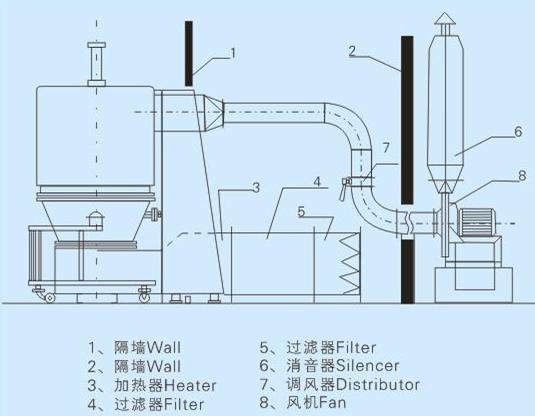

Product Flowchart:

Site real shot pictures:

Prev:Activated carbon (carbon-impregnated) dried dedicated production line