Food engineering industry

CONTACT US

If you need, please contact us in time!

Contacts:Ms Annie Shi

Telephone:+86-519-88908088

Mobile:+86-15861862227

Address:No.68 Shunhe Road, Jiaoxi Zhenglu Town, Changzhou City 213116, Jiangsu,China

Food engineering industry

Soy, pea protein, soybean production line dedicated flash drying

Detailed description

Soy, pea protein, soybean production line dedicated flash drying

Project Description:

Soy bean dregs tofu, soy milk and soy processing byproduct, usually about 80% moisture content, high moisture content, and contains a certain amount of oil, are particularly vulnerable to infection and microbial fermentation and spoilage, so fresh drying time is a critical step Okara Okara can be widely applied.

Studies have shown that 16% to 25% soy bean dregs of the total generated in the production of quality beans. Okara is rich in nutrients, including protein, dietary fiber, fat, vitamins and flavonoids, can reduce plasma cholesterol levels, improve glycemic response and improve bowel function, with a very good value. However, due to the high moisture content of bean dregs, rough texture, it would be inappropriate for processing, storage and direct consumption. General sale as animal feed, or even directly discarded, resulting in a tremendous waste of resources and environmental pollution, and therefore how to effectively deal Okara become an urgent need to study and solve problems.

At present, there are a large drum dryer dregs , soybean residues paddle dryer , large microwave dryer dregs , soybean residues bundle dryers , etc., but very low drying efficiency, energy consumption, high cost of inputs, but with respect to the production to Okara He said processing capacity is still limited. Therefore, the development of high efficiency, energy saving, environmental characteristics Okara new drying technology development and drying equipment is very important.

Our design and development of large soybean dregs dietary fiber effective flash dryer for soybean dietary fiber products are hydrophilic, high initial moisture content, high protein content, viscous nature of the characteristics, taken a series of original and unique technology processes to be addressed to ensure good drying effect, yield, low energy consumption, to achieve energy-efficient than conventional flash dryer 15% to 25% of the results.

Item Description:

Dietary fiber is not the word had appeared before 1970 nutrition in general is not easily digested food nutrients, mainly from the cell walls of plants, including cellulose, hemicellulose, resin, pectin and lignin Wait. Dietary fiber is indispensable to a healthy diet, fiber in maintaining a healthy digestive system plays an important role, while adequate intake of fiber can also prevent cardiovascular disease, cancer, diabetes and other diseases. Fiber can clean the digestive wall and enhance digestion, the fibers can be diluted while accelerating food carcinogens and toxic substances removal and to protect the fragile digestive tract and prevent colon cancer. Fiber can slow digestion rate and the most rapid excretion of cholesterol, thus allowing blood sugar and cholesterol control in the optimal level. Drying Process

Description:

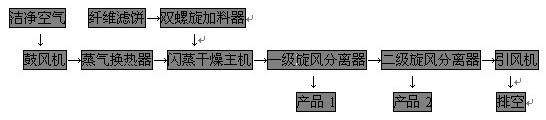

wet material from soybean residues twin screw feeder into the dryer host, under the effect of a strong high-speed rotation of the agitator, the material by impact, friction and shearing effect is dispersed, the bulk material quickly crushed full contact with the hot air contact, heat dried. Dehydrated dry powder with the heat rises, the large ring particle retention rating, small particles from the dryer exhaust outside the center of the ring by the cyclone recovery, not dry or bulk materials Shuaixiang wall by centrifugal force, a drop in the end again section was crushed dried. Since the gas-solid flow in rotating and the inertia of the solid phase is greater than the gas phase, the larger the relative velocity between solid and gas phases, enhanced heat transfer properties of the two phases, so it strengthens the process.

Advantages reflect:

for material properties of soybean dietary fiber - fiber product itself has a strong hydrophilic, while the initial moisture material and higher than 75%. I designed the effective flash dryer yield, low energy consumption. To achieve energy saving than conventional flash dryer 15% --25% of the effect; technical process (flow chart):