Vacuum and conduction drying series

CONTACT US

If you need, please contact us in time!

Contacts:Ms Annie Shi

Telephone:+86-519-88908088

Mobile:+86-15861862227

Address:No.68 Shunhe Road, Jiaoxi Zhenglu Town, Changzhou City 213116, Jiangsu,China

Vacuum and conduction drying series

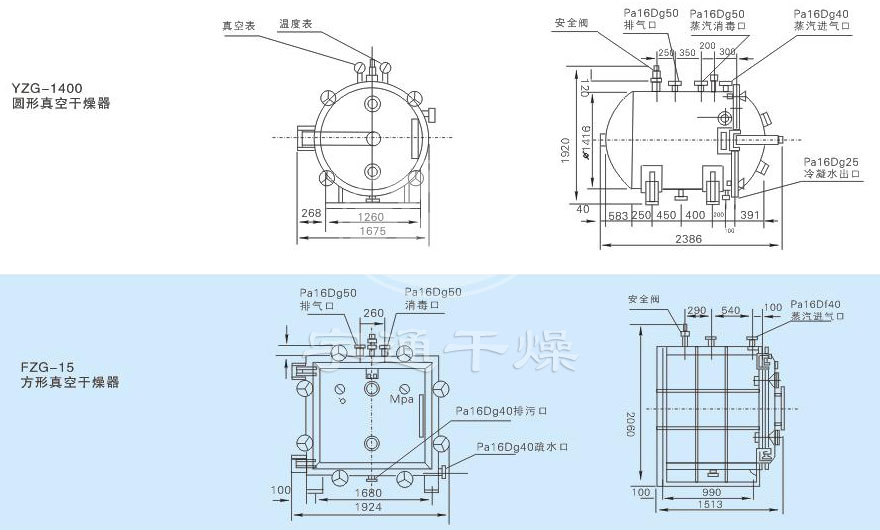

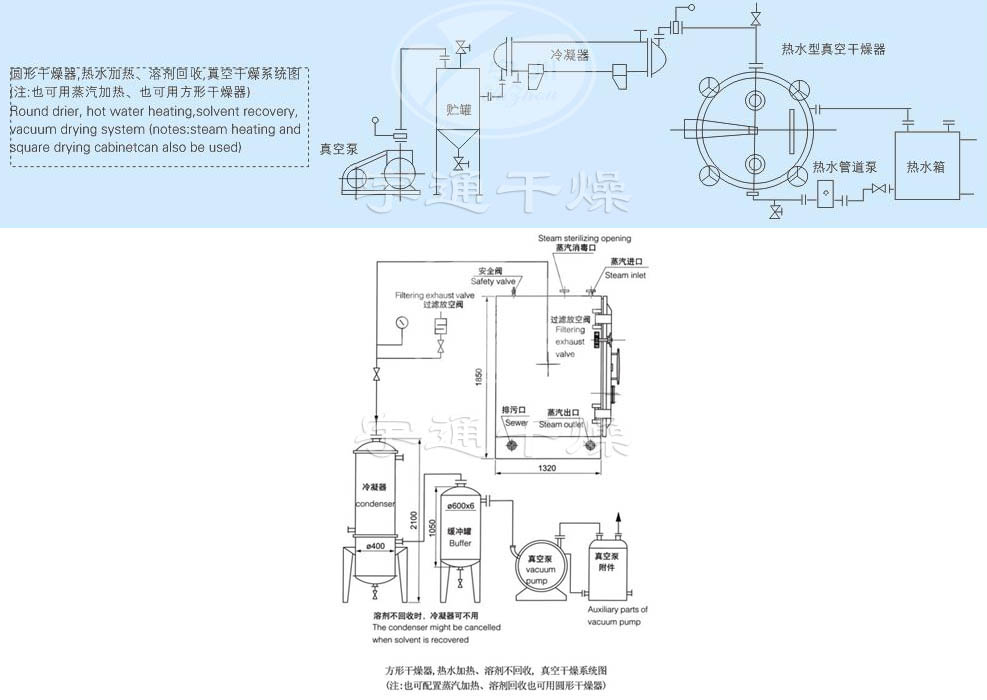

YZG / FZG Series Vacuum Dryer

Detailed description

|

Specification / Name |

YZG-600 |

YZG-800 |

YZG-1000 |

YZG-1400A |

FZG-10 |

FZG-15 |

FZG-20 |

|

Oven internal dimensions (mm) |

F600 × 976 |

F800 × 1247 |

F1000 × 1527 |

F1400 × 2054 |

1500×1060×1220 |

1500×1400×1220 |

1500×1800×1220 |

|

Oven External dimensions (mm) |

1135 × 810 × |

1700 × 1045 × |

1693 × 1190 × |

2386 × 1675 × |

1513 × 1924 × |

1513 × 1924 × |

1513 × 1924 × |

|

Drying rack layer |

4 |

4 |

6 |

8 |

5 |

8 |

12 |

|

Interlayer distance (mm) |

82 |

82 |

102 |

102 |

122 |

122 |

122 |

|

Baking tray size (mm) |

310 × 600 × |

520 × 410 × |

520 × 410 × |

460 × 640 × |

460 × 640 × |

460 × 640 × |

460×640×45 |

|

Number of baking tray |

4 |

8 |

12 |

32 |

20 |

32 |

48 |

|

Drying rack tube so that pressure (MPa) |

≤0.784 |

≤0.784 |

≤0.784 |

≤0.784 |

≤0.784 |

≤0.784 |

≤0.784 |

|

Drying rack temperature (℃) |

35-150 |

35-150 |

35-150 |

35-150 |

35-150 |

35-150 |

35-150 |

|

The degree of vacuum inside the load (MPa) |

-0.09 ~ 0.096 |

||||||

|

In -0.1MPa, the heating temperature 110oC, water gasification rate |

7.2 |

7.2 |

7.2 |

7.2 |

7.2 |

7.2 |

7.2 |

|

With a condenser, the vacuum pump models, power (kw) |

2X-15A |

2X-30A |

2X-30A |

2X-70A |

2X-70A |

2X-70A |

2X-90A |

|

When not in condenser vacuum pump model, power (kw) |

SK-0.8 |

SK-2.7 |

SK-3 |

SK-6 |

SK-3 |

SK-6 |

SK-6 |

|

Oven Weight (kg) |

250 |

600 |

800 |

1400 |

1400 |

2100 |

3200 |