Vacuum and conduction drying series

CONTACT US

If you need, please contact us in time!

Contacts:Ms Annie Shi

Telephone:+86-519-88908088

Mobile:+86-15861862227

Address:No.68 Shunhe Road, Jiaoxi Zhenglu Town, Changzhou City 213116, Jiangsu,China

Vacuum and conduction drying series

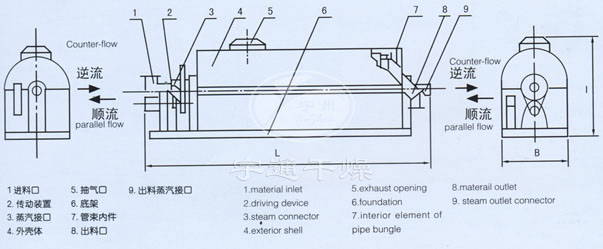

GZG series tube bundle dryer

Detailed description

|

Specifications Model |

Speed (rpm) |

Host power (kw) |

Heat exchange area (m2) |

Drying capacity (water evaporation kg / m2h) |

Dimensions (L * W * H) (mm) |

Weight (T) |

|

GZG50 |

5-8 |

5.5 |

50 |

4.7 |

8032×1712×2250 |

9.0 |

|

GZG100 |

5-8 |

7.5 |

100 |

4.7 |

9100×1912×2470 |

14.0 |

|

GZG150 |

5-8 |

11 |

150 |

4.7 |

8500×2212×2810 |

18.5 |

|

GZG200 |

5-8 |

11 |

200 |

4.7 |

10000×2212×2810 |

20.0 |

|

GZG250 |

5-8 |

15 |

250 |

4.7 |

10200×2212×2810 |

23.0 |

|

GZG300 |

5-8 |

twenty two |

300 |

4.7 |

10784×2488×3383 |

26.0 |

|

GZG350 |

5-8 |

30 |

350 |

4.7 |

12048×2488×3383 |

28.0 |

|

GZG400 |

5-8 |

30 |

400 |

4.7 |

13048×2488×3383 |

30.0 |

|

GZG500 |

5-8 |

45 |

500 |

4.7 |

11298×2982×3965 |

40.0 |

|

GZG600 |

5-8 |

75 |

600 |

4.7 |

12298×2982×4165 |

45.0 |

|

GZG700 |

5-8 |

75 |

700 |

4.7 |

13298×2982×4365 |

51.0 |

Material properties:

|

Common types of light material part |

Water into the machine |

A water machine |

Dry strength evaporated kgH2O / m2h |

Energy (KJ / kg evaporated water) |

|

Straw |

55% |

3-5% |

2.5-3 |

3500-3800 |

|

Corn fiber |

60% |

10-12% |

4.8 |

|

|

Fermentation meal |

45% |

12-13% |

4.7 |

|

|

Wood chips |

20% |

2-3% |

4.3 |

|

|

Potato fiber |

65% |

10-12% |

4.8 |

|

|

Beer tank, wine tank |

65% |

10-12% |

4.9 |

|

|

Feed carrier |

16% |

6-8% |

4.2 |

|

|

Rapeseed |

60% |

5-7% |

4.5 |

|

|

Blood, baking powder |

35% |

10% |

4.4 |

|

|

bone meal |

40% |

10% |

4.6 |