Vacuum and conduction drying series

CONTACT US

If you need, please contact us in time!

Contacts:Ms Annie Shi

Telephone:+86-519-88908088

Mobile:+86-15861862227

Address:No.68 Shunhe Road, Jiaoxi Zhenglu Town, Changzhou City 213116, Jiangsu,China

Vacuum and conduction drying series

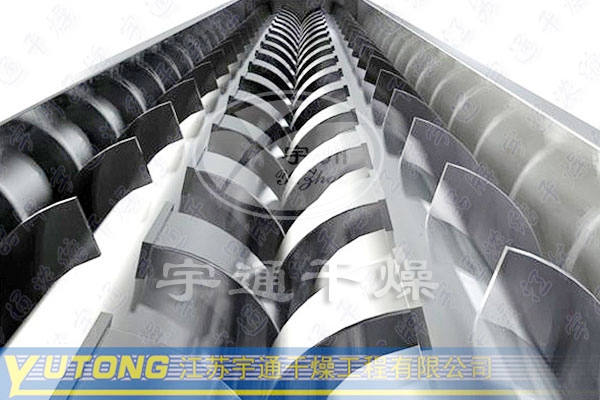

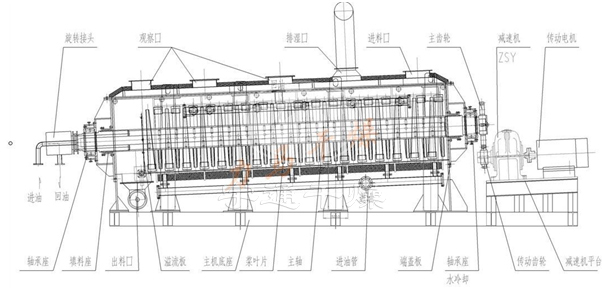

KJG Series Hollow Blade Dryer

Detailed description

|

Model |

KJG-2.7 |

KJG-9 |

KJG-13 |

KJG-18 |

KJG-24 |

KJG-29 |

KJG-36 |

KJG-41 |

|

Heat transfer area m2 |

2.7 |

9 |

13 |

18 |

twenty four |

29 |

36 |

41 |

|

Effective volume m3 |

0.06 |

0.32 |

0.59 |

1.09 |

1.53 |

1.85 |

2.42 |

2.8 |

|

Speed range rpm |

15-30 |

10-25 |

10-25 |

10-20 |

10-20 |

10-20 |

10-20 |

10-20 |

|

Power kw |

2.2 |

4.0 |

5.5 |

7.5 |

11 |

11 |

15 |

15 |

|

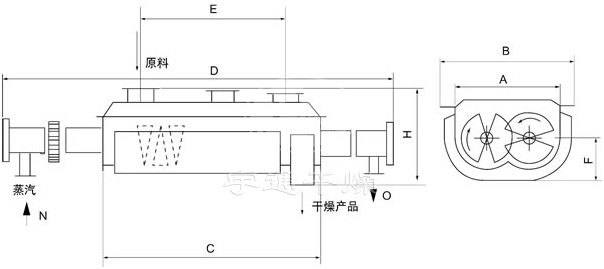

Body width A mm |

306 |

584 |

762 |

940 |

1118 |

1118 |

1296 |

1296 |

|

Total width B mm |

736 |

841 |

1066 |

1320 |

1474 |

1474 |

1676 |

1676 |

|

Body length C mm |

1956 |

2820 |

3048 |

3328 |

3454 |

4114 |

4115 |

4724 |

|

Total length D mm |

2972 |

4876 |

5486 |

5918 |

6147 |

6808 |

6960 |

7570 |

|

Access to materials from the E mm |

1752 |

2540 |

2768 |

3048 |

3150 |

3810 |

3810 |

4420 |

|

Center height F mm |

380 |

380 |

534 |

610 |

762 |

762 |

915 |

915 |

|

Overall height G mm |

762 |

838 |

1092 |

1270 |

1524 |

1524 |

1778 |

1778 |

|

N-inch steam inlet |

(2) 3/4 |

(2) 3/4 |

(twenty one |

(twenty one |

(twenty one |

(twenty one |

(twenty one |

(twenty one |

|

Inch outlet O |

(2) 3/4 |

(2) 3/4 |

(twenty one |

(twenty one |

(twenty one |

(twenty one |

(twenty one |

(twenty one |

|

Model |

KJG-48 |

KJG-52 |

KJG-62 |

KJG-68 |

KJG-73 |

KJG-81 |

KJG-87 |

KJG-95 |

KJG-110 |

|

Heat transfer area m2 |

48 |

52 |

62 |

68 |

73 |

81 |

87 |

95 |

110 |

|

Effective volume m3 |

3.54 |

3.96 |

4.79 |

5.21 |

5.78 |

6.43 |

7.39 |

8.07 |

9.46 |

|

Speed range rpm |

10-20 |

10-20 |

10-20 |

10-20 |

5-15 |

5-15 |

5-15 |

5-15 |

5-10 |

|

Power kw |

30 |

30 |

45 |

45 |

55 |

55 |

75 |

75 |

95 |

|

Body width A mm |

1474 |

1474 |

1651 |

1652 |

1828 |

1828 |

2032 |

2032 |

2210 |

|

Total width B mm |

1854 |

1854 |

2134 |

2134 |

2286 |

2286 |

2438 |

2438 |

2668 |

|

Body length C mm |

4724 |

5258 |

5410 |

5842 |

5461 |

6020 |

5537 |

6124 |

6122 |

|

Total length D mm |

7772 |

8306 |

8865 |

9296 |

9119 |

9678 |

9119 |

9704 |

9880 |

|

Access to materials from the E mm |

4420 |

4954 |

4953 |

5384 |

5004 |

5562 |

5080 |

5664 |

5664 |

|

Center height F mm |

1066 |

1066 |

1220 |

1220 |

1220 |

1220 |

1220 |

1220 |

1220 |

|

Overall height G mm |

2032 |

2032 |

2362 |

2362 |

2464 |

2464 |

2566 |

2566 |

2668 |

|

N-inch steam inlet |

(2) 11/2 |

(2) 11/2 |

(2) 11/2 |

(2) 11/2 |

(2) 11/2 |

(2) 11/2 |

(2) 2 |

(2) 2 |

(2) 2 |

|

Inch outlet O |

(2) 11/2 |

(2) 11/2 |

(2) 11/2 |

(2) 11/2 |

(2) 11/2 |

(2) 11/2 |

(2) 2 |

(2) 2 |

|