Vacuum and conduction drying series

CONTACT US

If you need, please contact us in time!

Contacts:Ms Annie Shi

Telephone:+86-519-88908088

Mobile:+86-15861862227

Address:No.68 Shunhe Road, Jiaoxi Zhenglu Town, Changzhou City 213116, Jiangsu,China

Vacuum and conduction drying series

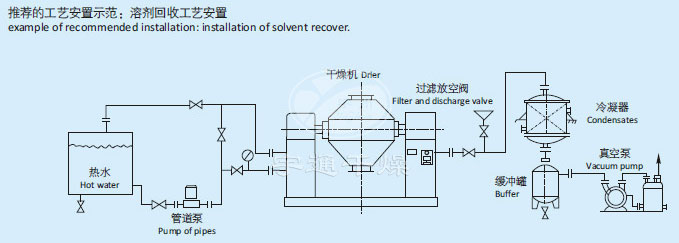

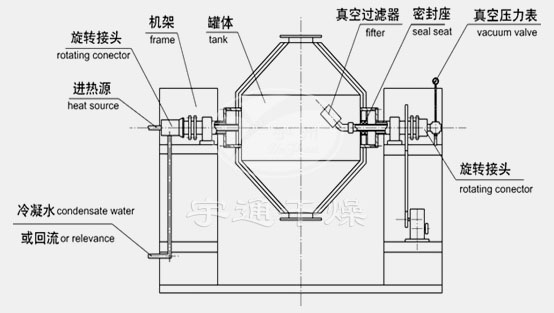

SZG Series Double Cone Rotary Vacuum Dryer

Detailed description

|

specification |

100 |

350 |

500 |

750 |

1000 |

1500 |

2000 |

3500 |

4500 |

|

Tank volume (L) |

100 |

350 |

500 |

750 |

1000 |

1500 |

2000 |

3500 |

4500 |

|

Loading volume (L) |

≤50 |

≤175 |

≤250 |

≤375 |

≤500 |

≤750 |

≤1000 |

≤1750 |

≤2250 |

|

Speed (rpm) |

3 to 13 |

||||||||

|

Motor power (kw) |

0.75 |

1.1 |

1.5 |

2 |

3 |

3 |

4 |

5.5 |

7.5 |

|

Covers an area of |

2160×800 |

2260×800 |

2350×800 |

2560×1000 |

2860×1300 |

3060×1300 |

3260×1400 |

3760×1800 |

3960×2000 |

|

Rotating height (h) |

1750 |

2100 |

2250 |

2490 |

2800 |

2940 |

2990 |

3490 |

4100 |

|

Tank design pressure (MPa) |

-0.1 ~ 0.15 |

||||||||

|

Jacket design pressure (MPa) |

≤0.3 |

||||||||

|

Working Temperature (℃) |

Jacketed tank ≤85 ≤140 |

||||||||

|

With a condenser, the vacuum pump models, power (kw) |

2X-15A |

2X-15A |

2X-30A |

2X-30A |

2X-70A |

JZJX300-8 |

JZJX300-4 |

JZJX600-8 |

JZJX600-4 |

|

When not in condenser vacuum pump model, power (kw) |

SK-0.4 |

SK-0.4 |

SK-0.8 |

SK-2.7B |

SK-2.7B |

SK-3 |

SK-6 |

SK-6 |

SK-9 |

|

Weight (kg) |

800 |

1100 |

1200 |

1500 |

2800 |

3300 |

3600 |

6400 |

7500 |