Vacuum and conduction drying series

CONTACT US

If you need, please contact us in time!

Contacts:Ms Annie Shi

Telephone:+86-519-88908088

Mobile:+86-15861862227

Address:No.68 Shunhe Road, Jiaoxi Zhenglu Town, Changzhou City 213116, Jiangsu,China

Vacuum and conduction drying series

ZKG Vacuum Harrow Dryer

Detailed description

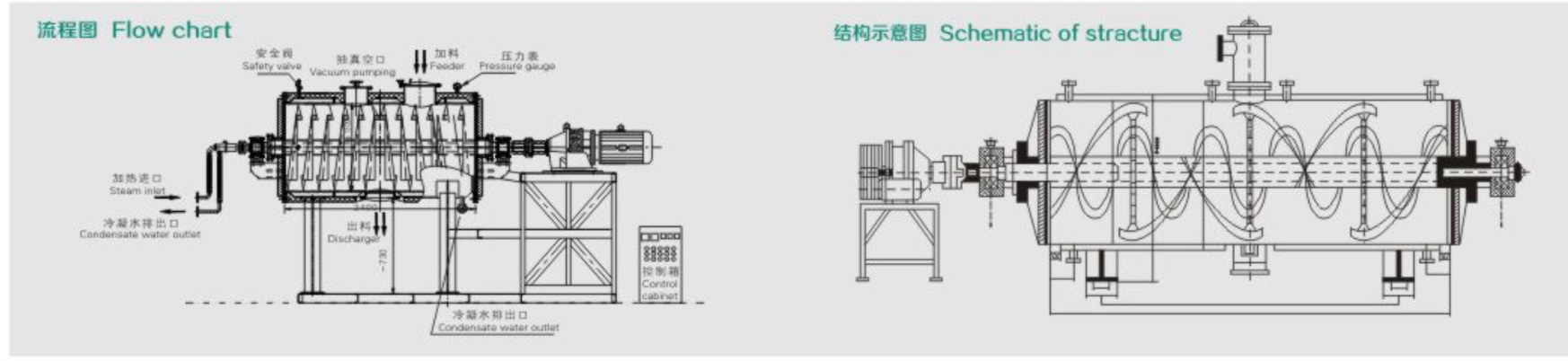

The whole device of Harrow drying machine is mainly composed of cylinder, transmission part, frame and other parts. After the dried material is added from the feeding port, the feeding port is tightly covered, steam is introduced into the jacket, and the vacuum pump is started. The main shaft of the dryer equipped with the harrow group is driven by a motor, which is decelerated by a speed reducer and then rotated forward and backward at a fixed rotation speed. The material moves to two sides along with the forward rotation of the harrow; when the harrow rotates in the opposite direction, the materials are collected from both sides to the middle. As the inside of the material is indirectly heated by steam while being evenly stirred by the harrow teeth, the moisture in the material is promoted to be gasified, and the dryer is emptied from the outlet of the vacuum pump under the action of the vacuum system.

二.Working principle of vacuum harrow dryer

The vacuum harrow dryer uses a steam jacket to indirectly heat materials and exhausts them under high vacuum, thus being especially suitable for drying materials that are not resistant to high temperature and easy to oxidize at high temperature or materials that easily produce powder during drying. The material to be dried is added from the middle of the upper square of the shell with the stirring of the continuously rotating harrow teeth, the surface of the material is continuously updated when contacting the wall of the shell, the material to be dried is indirectly heated by steam (or hot water, heat transfer oil), the moisture of the material is gasified, and the gasified moisture is pumped away by the vacuum pump in time. As the operating vacuum degree is relatively high, it is generally within the range of -0.08 - 0.096 MPa, and the water vapor pressure on the surface of the material to be dried is much greater than the water vapor pressure in the evaporation space in the dryer shell. So as to facilitate the discharge of moisture inside and on the surface of the material to be dried, facilitate the movement of water molecules of the material to be dried, and achieve the purpose of drying.

Prev:GLZ series vacuum ribbon dryer

Next:No Next