Mixing equipment

CONTACT US

If you need, please contact us in time!

Contacts:Ms Annie Shi

Telephone:+86-519-88908088

Mobile:+86-15861862227

Address:No.68 Shunhe Road, Jiaoxi Zhenglu Town, Changzhou City 213116, Jiangsu,China

Mixing equipment

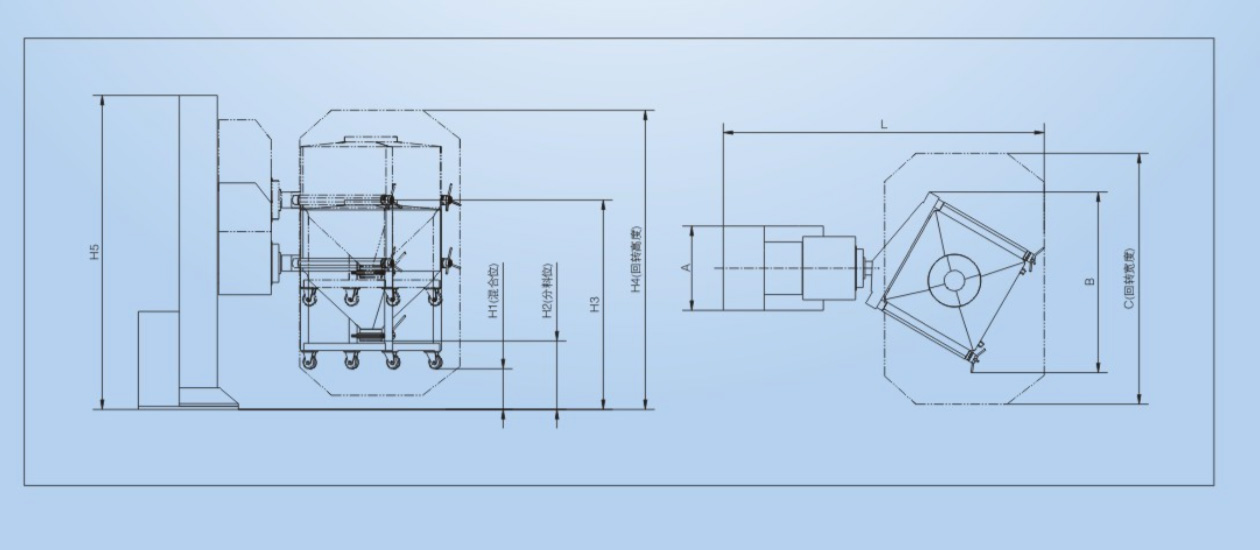

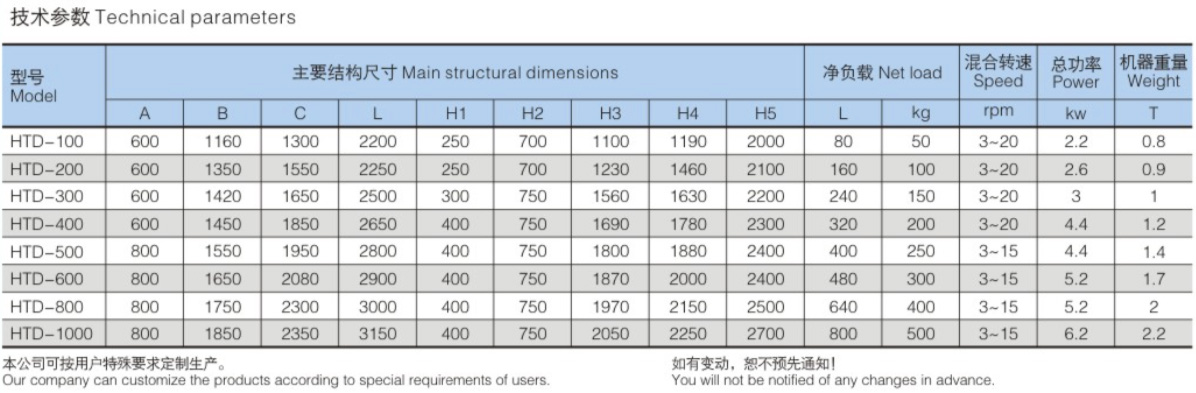

HTD COLUMN TYPE HOPPER MIXER

Detailed description

Function feature and the principle of action.

Purpose:

This machine is provided with such functions as automatic lifting, mixing, lowering, etc. A hopper mixer and several mixing hoppers of different specifications can meet the mixing requirements of diversified varieties and different batches of products. It is an ideal machine for mixing in pharmaceutical plants. It is also widely used in such industries as medicine, chemical industry, food, etc.

Principle:

The machine is composed of column, machine base, rotation crotch, driving system, braking system, control system, etc. Push the mixing hopper into the rotation crotch and lock the nuts. Start the control system to lift the hopper to the mixing height and position it reliably. The driving system will carry out automatic mixing according to the set time, rotation speed and other data. After the mixing operation is finished, the rotation crotch will stop vertically, the hopper will automatically fall to the ground, the machine will stop and process the data will be printed. Loosen the locknuts of the rotary crotch and push the hopper out and transfer it to the next procedure.

Feature:

The machine is a new machine researched and developed successfully by our company according to China’s actual conditions after absorbing and digesting internationally advanced technology. After mixing is finished, the hopper can continue to rise to the required height to facilitate discharging. The machine has such features as reasonable structure, stable performance, convenient operation, no dead corners, and no exposed bolts. The gyrator (mixing hopper) forms an included angle of 30°with the rotation axis. The materials in the mixing hopper rotate along with the gyrator and make tangential movement along the hopper walls, producing strong turning and high-speed tangential movement and achieving the best mixing effect. PLC automatic control is adopted. It is provided with the infrared safety device and the discharging butterfly valve with the mis-operation preventer to ensure safe production. The materials can go through different working procedures in the same vessel without the need of frequent material transferring, material charging, etc. the machine effectively controls dust pollution and cross contamination, reduces loss of materials, controls material layering, optimizes production processes, and fully meets the requirements for medicine production in GMP.