Waste salt drying industry

CONTACT US

If you need, please contact us in time!

Contacts:Ms Annie Shi

Telephone:+86-519-88908088

Mobile:+86-15861862227

Address:No.68 Shunhe Road, Jiaoxi Zhenglu Town, Changzhou City 213116, Jiangsu,China

Waste salt drying industry

Rubber accelerator, antioxidant dedicated rotary film evaporator

rubber accelerator refers to rubber vulcanization accelerator. Sulfur vulcanized rubber is mainly used to carry out, but the reaction of sulfur with the rubber is very slow, so the vulcanization accelerator emerged. Promoting agent is added rubber compound can induce the activation of the curing agent, thus speeding up the curing agent and ...

Detailed description

Rubber accelerator, antioxidant dedicated rotary film evaporator

project description:

Rubber accelerator refers to rubber vulcanization accelerator. Sulfur vulcanized rubber is mainly used to carry out, but the reaction of sulfur with the rubber is very slow, so the vulcanization accelerator emerged. Promoting agent is added rubber compound can induce curing agent activation, thereby accelerating the crosslinking reaction curing agent with the rubber molecules, to shorten the curing time and reduce the curing temperature effect.

Item Description:

Item Description:

Rubber accelerator refers to rubber vulcanization accelerator. Sulfur vulcanized rubber is mainly used to carry out, but the reaction of sulfur with the rubber is very slow, so the vulcanization accelerator emerged. Promoting agent is added rubber compound can induce curing agent activation, thereby accelerating the crosslinking reaction curing agent with the rubber molecules, to shorten the curing time and reduce the curing temperature effect. Vulcanization accelerator is mainly used by the chemical structure of the main points are sulfenamides, thiazoles, thiurams, there are some guanidines, thioureas and dithiocarbamate salts. Wherein the sulfenamide best overall performance, the most widely used.

Means capable of preventing or inhibiting antioxidant such as oxygen, heat, light, ozone, mechanical stress, heavy metal ions on the performance of damaged products, and to extend the storage life of the product ingredients. Reduce the phenomenon is called aging. With the conduct and development of rubber products and performance of the aging process that will gradually reduce the total loss of value.

Equipment summary:

Means capable of preventing or inhibiting antioxidant such as oxygen, heat, light, ozone, mechanical stress, heavy metal ions on the performance of damaged products, and to extend the storage life of the product ingredients. Reduce the phenomenon is called aging. With the conduct and development of rubber products and performance of the aging process that will gradually reduce the total loss of value.

Equipment summary:

GXZ series of highly efficient rotary film evaporator, the scraper evaporator, a forced deposition by rotating blades, new high efficiency evaporator can be a falling film evaporator under vacuum conditions, it is the heat transfer coefficient, high evaporation strength, overcurrent short time, operating flexibility, especially suitable for heat-sensitive materials shall, high viscosity materials and concentrated by evaporation and crystallization containing particulate material, removing solvent degassing, distillation purification. Our company has been manufacturing such equipment for many years, and accumulated a wealth of manufacturing experience. For a long time customer closely actual production and market demand, to meet user process requirements, select the appropriate and reasonable structure, reliable manufacturing ensure high quality, tooling equipment, testing methods and product design and other aspects of continuous improvement and increasingly perfect, has made a remarkable achievement, technical level and product quality in the domestic leading level.

working principle:

working principle:

Material enters the heating zone from the top of the radial evaporator, distributed through distributor to the evaporator heating wall, then rotate the wiper rolling the material is uniformly heated surface continuously scraped into a uniform thickness of the liquid film, and the downward spiral advance. In this process, the rotation of the wiper rolling to ensure continuous and uniform film to produce high-speed turbulence and prevent the liquid film surface heating coke, fouling, thereby improving the overall transfer coefficient. Light components are formed by evaporation vapor stream to rise through the vapor-liquid separator to reach the external condenser and evaporator are directly connected, the heavy component is discharged from the evaporator at the bottom of the cone. A unique distributor not only has a uniform material flow to the inner wall of the evaporator, to prevent the material spilled inside the evaporator is injected into the steam flow, also preventing just entering the material here flashed in favor of the elimination of foam, the material only evaporate along the heating surface. In the upper wiped film evaporator with a design based on the material properties of a centrifugal separator, the steam flow will rise droplets separated and return to the hopper.

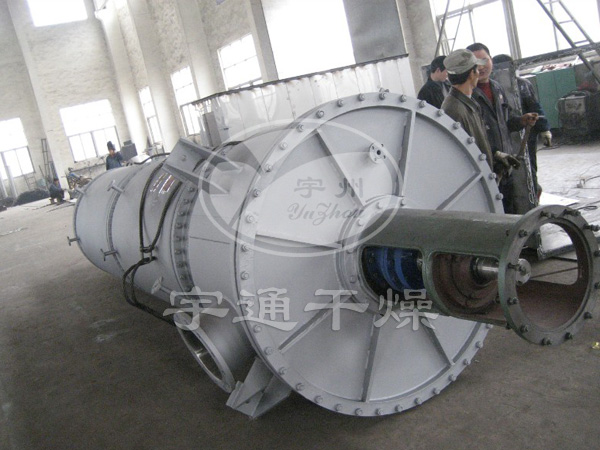

Site real shot pictures:

Site real shot pictures: