Chemical industry

CONTACT US

If you need, please contact us in time!

Contacts:Ms Annie Shi

Telephone:+86-519-88908088

Mobile:+86-15861862227

Address:No.68 Shunhe Road, Jiaoxi Zhenglu Town, Changzhou City 213116, Jiangsu,China

Chemical industry

Asphalt special vacuum tray dryer

My company designed and manufactured vacuum disc dryer is continuous improvement in the absorption of foreign technology, innovative energy-efficient continuous drying equipment. Its unique structure and operating principle determines that it has high thermal efficiency,

Detailed description

Asphalt special vacuum tray dryer

project description:

I designed the production of vacuum disc dryer is continuous improvement in the absorption of foreign technology, innovative energy-efficient continuous drying equipment. Its unique structure and operating principle determines that it has high thermal efficiency, low energy consumption, small footprint, simple configuration, easy to operate controls. Good operating environment and so on. Widely used in chemical, pharmaceutical, pesticide, feed, new materials and other industry products drying operation.

Material Overview:

Asphalt is a dark brown complex mixture of hydrocarbons and their derivatives with different molecular weight composed of non-metallic and is a high viscous organic liquid is liquid black surface, can be soluble in carbon disulfide. Asphalt is a waterproof and corrosion of organic gelling material. Asphalt can be divided into coal tar pitch, petroleum asphalt and natural asphalt are three: which is a byproduct of coking coal tar pitch. Asphalt is the residue after the distillation of crude oil. Natural asphalt is stored in the ground, and some formed seam or deposited on the surface of the earth's crust. Bitumen is mainly used in paints, plastics, rubber and other industrial and paving the like.

Working principle and process:

Wet material containing the solvent continuously through the screw feeder hopper to join the host material in the stirring motor under the action of the upper part of the dryer is continuously applied to the first layer of drying plate, rake leaves rake arm with a rotary motion to do so continuously rake leaves turn copied material, so that the material fully absorb heat index material along the spiral flow through the disk surface drying, the material was dried in a small disk is transferred to the outer edge and the outer edge of the large drying plate fell below the outer edge, in large to the dried material on the disc in the middle of moving from a small blanking mouth fall into the lower tray drying, large drying plates are arranged alternately, the material can be continuous through the whole dryer, dry hollow plate through a heating medium HTF . By the end of the heating medium into the dry disk tray drying, derived from the other end. The dried material falls from the last layer of drying plate with a cooling of the housing bottom, the last being transferred to rake leaves into the bottom of the discharge port of the feed screw, and by the buffer tank from the plane. The moisture from the material after the solvent evaporates escape, after the settlement provided by the buffer tank at the top of the extraction solvent into the buffer tank via the condenser condensate recovery, wet air and finally empty.

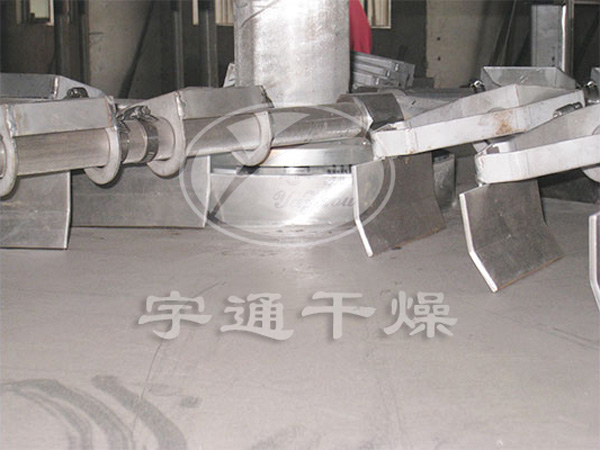

Scene real pictures: