Extracting and concentrating equipment

CONTACT US

If you need, please contact us in time!

Contacts:Ms Annie Shi

Telephone:+86-519-88908088

Mobile:+86-15861862227

Address:No.68 Shunhe Road, Jiaoxi Zhenglu Town, Changzhou City 213116, Jiangsu,China

Extracting and concentrating equipment

CQT series of continuous high - performance liquid - gas - solid extraction tower

Detailed description

Overview

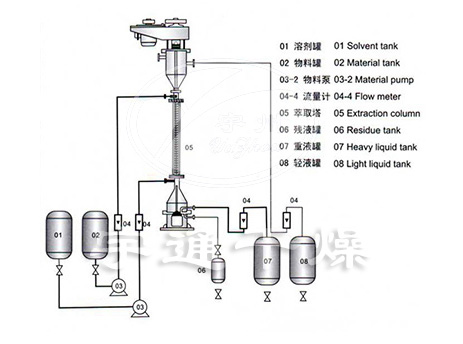

The CQT series continuous high performance liquid-gas-solid extraction column produced by our company is improved on the basis of single-tank two-liquid stirring mixing extraction, static multi-stage countercurrent extraction, static and dynamic emulsification extraction machine. Using the dynamic ring and the working principle of static ring, heavy liquid and light liquid into the form of convection, so that droplets full contact, without emulsifying phenomenon, to achieve a continuous extraction process purposes, is the more advanced and efficient extraction Tower, by many users.

working principle

The liquid-liquid-solid continuous extraction column is composed of a vertical cylinder with a horizontal stationary ring baffle. Static ring baffle plate for the center hole, static ring baffle cylinder will be divided into a series of extraction chamber. The center of the extraction chamber has a moving ring whose diameter is slightly smaller than the opening diameter of the stationary ring baffle. A series of moving rings are mounted parallel to the shaft so that the moving ring and the shaft can be easily loaded into the tower. Between the two pairs of flanges is a mixed section, liquid - liquid mass transfer process is mainly here to complete. The intermediate upper flange to the top plate portion is an upper separation section for clarification of the light liquid; the middle lower flange to the bottom flange portion is the lower separation section as the lower separation section for clarification of the heavy liquid. In the mixing section above and below the large-hole sieve, heavy phase from the bottom of the screen into the tower, the light phase from the top of the sieve into the tower, the role of the sieve is to reduce the liquid stirring to enhance the clarification of the sub- Phase effect.

And other tower extraction equipment, work light phase and heavy phase from the lower part of the tower and the tower into the turntable tower, the two-phase countercurrent contact in the tower, the role of the turntable, the formation of small droplets dispersed phase, increasing the two liquid And the light phase and heavy phase of the extraction process are respectively discharged from the light liquid outlet and the heavy liquid outlet.

Applications

For liquid - gas, liquid - liquid, liquid - solid mass transfer system. Extraction of the extraction process is the use of two immiscible liquid phase in the various components (including the target product) of different solubility, so as to achieve the purpose of separation. It is a commonly used unit operation for separating liquid mixtures. It is widely used in fermentation and bioengineering. It can not only extract and enrich the product, but also remove some other similar substances to obtain the initial purification of the product.

Pharmaceutical industrialization combined class

① sulfa drugs and other drug production process;

② The fermentation broth extracted with antibiotics;

③ to send alcohol liquid extract synthetic pigment;

④ removal of phenols from wastewater.

Traditional Chinese medicines:

① The extracted with an organic solvent from the acidic medicinal plant extract alkaloids;

② The organic solvent extraction flavonoids from Ginkgo biloba; for the extraction of a variety of chemical constituents of traditional Chinese medicine, polysaccharides, proteins (SOD) phenols, Saponins, flavonoids, alkaloids, steroids and so on.

Food Food Industry

for milk protein extraction process, Triton powder, queen bee oar, food additives, spices and other flavors.

Pigments:

purification of natural pigment separation; Pan eggplant red (yellow) pigment, wolfberry red (yellow) pigment, bicolor red (yellow) pigment, Chrysanthemum flavin, Mongolia took other elements.

Environmental categories: for the removal of phenol wastewater treatment.

Technical Parameters

|

Tower diameterΦ |

Plate height(mm) |

Total height(mm) |

Flow rate(L/h) |

Motor(kw) |

speed |

Distance between the static and dynamic ring |

Remarks |

|

50 |

600 |

~1600 |

15-30 |

0.75 |

0~300 |

25-50 |

Insulation sets |

|

75 |

800 |

~2200 |

25-50 |

1.1 |

0~300 |

25-50 |

Insulation sets |

|

100 |

1100 |

~2800 |

80-110 |

1.5 |

0~300 |

25-50 |

Insulation sets |

|

150 |

1500 |

~3200 |

120-160 |

2.2 |

0~250 |

25-50 |

Insulation sets |

|

200 |

2000 |

~4600 |

200-260 |

3 |

0~200 |

25-50 |

Insulation sets |

|

300 |

3000 |

~6400 |

350-450 |

4 |

0~160 |

25-50 |

Insulation sets |

|

400 |

4000 |

~8000 |

600-1000 |

5.5 |

0~160 |

25-50 |

Insulation sets |

|

500 |

5000 |

~10000 |

1000-2000 |

5.5 |

0~160 |

25-50 |

Insulation sets |

|

600 |

6000 |

~12500 |

2000-3000 |

7.5 |

0~130 |

25-50 |

Insulation sets |

Note: 1, the choice of material according to the process requirements, the use of stainless steel SUS304, SS316L, coated nickel-phosphorus, or PTFE; 2, the user has special requirements can be designed and manufactured.