Extracting and concentrating equipment

CONTACT US

If you need, please contact us in time!

Contacts:Ms Annie Shi

Telephone:+86-519-88908088

Mobile:+86-15861862227

Address:No.68 Shunhe Road, Jiaoxi Zhenglu Town, Changzhou City 213116, Jiangsu,China

Extracting and concentrating equipment

GXZ series of highly efficient rotary film evaporator

Detailed description

product description:

GXZ series of highly efficient rotary film evaporator, the scraper evaporator, a forced deposition by rotating blades, new high efficiency evaporator can be a falling film evaporator under vacuum conditions, it is the heat transfer coefficient, high evaporation strength, overcurrent short time, operating flexibility, especially suitable for heat-sensitive materials shall, high viscosity materials and concentrated by evaporation and crystallization containing particulate material, removing solvent degassing, distillation purification. Thus, in the chemical, petrochemical, pharmaceutical, pesticide, cosmetic, food, chemical and other industries widely used.

Our company has been manufacturing such equipment for many years, and accumulated a wealth of manufacturing experience. For a long time customer closely actual production and market demand, to meet user process requirements, select the appropriate and reasonable structure, reliable manufacturing ensure high quality, tooling equipment, testing methods and product design and other aspects of continuous improvement and increasingly perfect, has made a remarkable achievement, technical level and product quality in the domestic leading level.

working principle:

Material enters the heating zone from the top of the radial evaporator, distributed through distributor to the evaporator heating wall, then rotate the wiper rolling the material is uniformly heated surface continuously scraped into a uniform thickness of the liquid film, and the downward spiral advance. In this process, the rotation of the wiper rolling to ensure continuous and uniform film to produce high-speed turbulence and prevent the liquid film surface heating coke, fouling, thereby improving the overall transfer coefficient. Light components are formed by evaporation vapor stream to rise through the vapor-liquid separator to reach the external condenser and evaporator are directly connected, the heavy component is discharged from the evaporator at the bottom of the cone.

A unique distributor not only has a uniform material flow to the inner wall of the evaporator, to prevent the material spilled inside the evaporator is injected into the steam flow, also preventing just entering the material here flashed in favor of the elimination of foam, the material only evaporate along the heating surface. In the upper wiped film evaporator with a design based on the material properties of a centrifugal separator, the steam flow will rise droplets separated and return to the hopper.

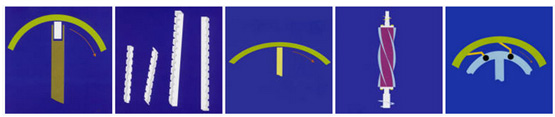

Scraper type:

Due to the movement of the blade, the material is constantly scrape the surface of a thin film evaporator, the material into a turbulent state, in order to achieve the effect of thin film evaporation. Depending on the viscosity and other properties of the material, the evaporator can be divided into the following blade form:

Activities scraper : Scraper is a basic activity, the most common form of the blade. Activities are in the form of scraper: SR-type, SL-type, the DR type, the DL type, the catheter has a groove inclination angle 30 °, 45 ° or 60 °.

Fixed blade: fixed blade are made of metal, which is rigidly connected to the rotor blade length of the barrel with the evaporation gap rotating blades and the inner wall of the barrel evaporation i only 1 + 2mm, demanding precision machining and installation, it is especially suitable for high viscosity and easily from the foam material concentrated by evaporation, solvent removal or purification.

Spiral blade: The blade applies to poor mobility, easy to scale, and concentrated ultra-high viscosity materials. When the rotor is rotated by the helical blade thrust, smooth downward flow of the concentrate material.

Scraper hinge: hinge blade easily adapted to the heated surface fouling or medium viscosity materials.

Features:

Following unique benefits rotary film evaporator available, conventional film evaporator can not be compared:

1. a minimum pressure loss

in the high rotary film evaporator, the stream and the secondary evaporation vapor stream are two separate channel: evaporation material along the inner wall of the cylinder (mandatory deposition) film falling down, and the evaporation surface evaporation of the secondary steam from the center of the cylinder space almost unimpeded leaving the evaporator, the pressure loss (or resistance drop) is minimal.

2. The operation can be achieved under vacuum conditions of true

positive since the secondary vapor from the evaporator to the condenser face minimal resistance, so that the entire evaporation surface of the evaporator tube wall to maintain a high degree of vacuum (up -750mmHg), almost equal the degree of vacuum system exports, due to the improvement of the degree of vacuum, effectively reduces the boiling point of the material being processed.

3. High heat transfer coefficient, high evaporation intensity

boiling point decreases with increasing temperature difference between the heat medium; the film was a turbulent state, reducing the thermal resistance; while suppressing material on the wall of coking, scaling, but also improve evaporation tube wall heat transfer coefficient; therefore efficient rotary film evaporator heat transfer coefficient can be as high Italian 8000KJ / h.m2 ℃, and therefore its high evaporation intensity.

4. low temperature evaporation

Due to evaporation cylinder can maintain a high degree of vacuum, the boiling point of the material to be processed is greatly reduced, so are particularly suitable for heat-sensitive materials at low temperature evaporation.

5. short flow time

Material flow in the evaporator is short, about 10 seconds or so; for a scraper common activities, and scraping end face with guide grooves of animals, the bevel is typically 45 ℃, changing the angle of the bevel may change over time, the material in the blow under Board shave moving, downward spiral away from evaporator. Reduced flow time, effectively preventing decomposition, polymerization of the product during the process of evaporation or deterioration.

6. use low grade steam

Steam is a commonly used medium heat, due to lower the boiling point of the material, ensuring the same t condition, it can reduce the heating medium temperature, use of low grade steam, conducive to the comprehensive utilization of energy.

7. strong adaptability and ease of operation

Unique design makes the product available to handle some conventional evaporators tricky high viscosity, containing particles, heat-sensitive and susceptible to crystallization of the material.

Rotary film evaporator operating flexibility, stable operating conditions, and low maintenance, and easy maintenance.

Technical Parameters:

|

Effective evaporation area m2 |

Dimensions mm |

equipment |

||||||||||

|

A total height of the device |

Heating cylinder height B |

C separation feeding tube |

Barrel diameter D |

High E mounting bracket |

Motor reducer F |

Seat pitch G |

Dn |

Motor power Kw |

Pressure MPa |

Total weight (approximately) Kg |

||

|

Jacket |

Inner tube |

|||||||||||

|

0.5 |

2205 |

800 |

500 |

273 |

1365 |

680 |

480 |

210 |

1.50 |

0.4 |

<-0095 |

460 |

|

1 |

3990 |

1500 |

500 |

278 |

1795 |

1445 |

541 |

219 |

2.2 |

0.4 |

<-0095 |

680 |

|

2 |

4470 |

1830 |

755 |

462 |

2455 |

1565 |

843 |

400 |

3.0 |

0.4 |

<-0095 |

1100 |

|

4 |

5490 |

2630 |

844 |

712 |

3511 |

1565 |

1003 |

600 |

5.5 |

0.4 |

<-0095 |

1950 |

|

6 |

6275 |

2890 |

844 |

912 |

3817 |

1944 |

1236 |

800 |

7.5 |

0.4 |

<-0095 |

2980 |

|

8 |

6910 |

3658 |

844 |

916 |

4587 |

1909 |

1236 |

800 |

7.5 |

0.4 |

<-0095 |

3550 |

|

10 |

6960 |

3658 |

900 |

1112 |

4542 |

1918 |

1567 |

1000 |

7.4 |

0.4 |

<-0095 |

4880 |

|

12 |

7460 |

3658 |

1003 |

1316 |

4985 |

1998 |

1909 |

1200 |

11 |

0.4 |

<-0095 |

6300 |

Notes:

1. The above dimensions may vary slightly from the actual equipment change, by reference to the order after the drawings provided by the company prevail;

2. Table D represents a heavy jacket outside diameter, Dn represents the inner diameter of the evaporator barrel;

3 . jacket pressure: 0.4MPa steam by conventional design, but also be designed according to user requirements, when using thermal oil, also can be designed;

4. the evaporator tube vacuum: regular press -0.09MPa (about -680mmHg), users can also be required to achieve -0.095MPa (about -720mmHg) and -0.0986Mpa (about 750mmHg));

5. the master cylinder (contact parts) and jacket material: according to the actual needs of the user and, using carbon steel, SUS304,316L, 316Ti or titanium, etc;

6. total weight: not including the weight of the material

Applications:

In the heat exchange project, wiped film evaporator to give wide lack of applications. Especially for heat-sensitive materials, short residence time of the heat exchange, wiped film has better thermal exchange and scraping through different membrane design can distilling complex products. Wiped film evaporator is used in the following areas have been concentrated by evaporation off the solvent, stripping reaction, degassing, deodorization (gas) for the purpose of flavor, achieved good results.

In medicine: antibiotics, sugar, Thunder Teng, astragalus and other herbs, methylimidazole, single nitrile amine intermediates;

light food: fruit juice, gravy, colors, flavors, fragrances, enzymes, lactic acid, xylose, starch sugar, potassium sorbate;

oil cosmetic: lecithin, VE, cod liver oil, oleic acid, glycerol, fatty acids, waste lubricating oil, alkyl polyglycosides, alcohol ether sulfates and the like;

synthetic resins: polyamide resins, epoxy , paraformaldehyde, PPS (polypropylene sebacic acid esters), PBT, acrylic acid ester;

synthetic fibers: PTA, DMT, carbon fiber, polytetrahydrofuran, polyether polyols and the like;

petrochemical: TDI, MDI, trimethyl hydroquinone, trimethylolpropane, sodium hydroxide;

pesticides bio: acetochlor, metolachlor, chlorpyrifos, furan phenol, Guangmieling, herbicides, insecticides, herbicides, mites agent;

wastewater : inorganic wastewater;

Prev:CQT series of continuous high - performance liquid - gas - solid extraction tower